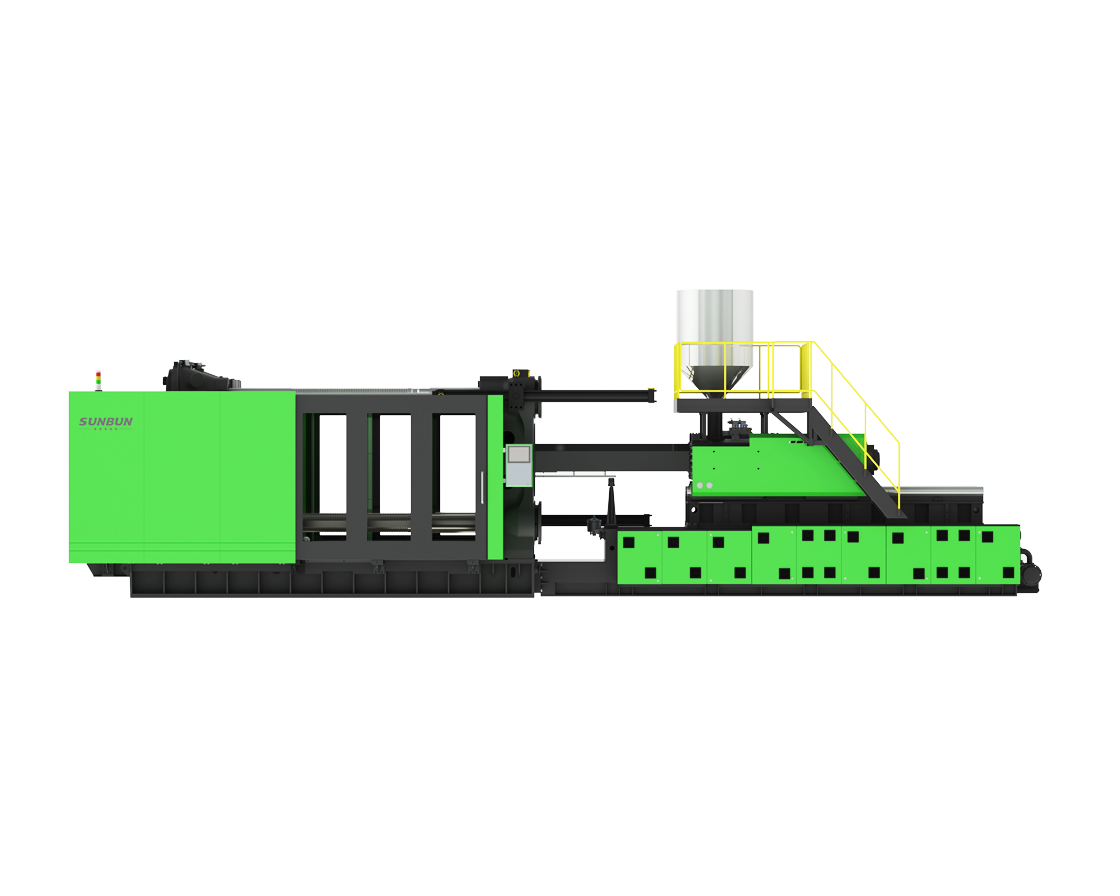

Two-platen injection molding machine

? Compact body design, occupying a small footprint.

? Large opening stroke, suitable for deep cavity molds.

? Better mold clamping balance.

? More energy-efficient than three-plate injection molding machines of the same tonnage.

? Low operating cost, as it features a non-tie-bar structure that eliminates the need for lubrication, saving a significant amount of lubricating oil. It also requires simple maintenance and upkeep.

? No mold adjustment is required, making it easy to operate.

? Superior mold capacity over a wide range.Mold capacity is a critical technical parameter in the locking mechanism of an injection molding machine, and it directly affects the practical range of the machine. A large mold capacity enables the machine to accommodate the production needs of both thin and thick molds.

? When a two-plate injection molding machine generates locking force, the tension section (length under tension) of the tie bar is relatively short. The thickness of the mold corresponds to the length of the tension section. Therefore, the deformation generated by the tie bar with such a short tension section is minimal.